Recognizing the value unitization has brought to the construction industry, MG McGrath has developed a way to apply this approach across a wider variety of projects including low-rise and mid-rise buildings. Unitized systems reduce risk, speed up the project schedule, improve performance, and minimize waste. We have a rich history designing, fabricating and installing glass+ and metals+ systems and leverage that expertise when deciding when to deploy stick-built vs unitized systems. Our unitized wall systems are fabricated, assembled, and glazed in our controlled shop thus minimizing the time our crews spend in unpredictable field conditions for higher levels of safety and quality.

UNITIZED CURTAIN WALL SYSTEMS

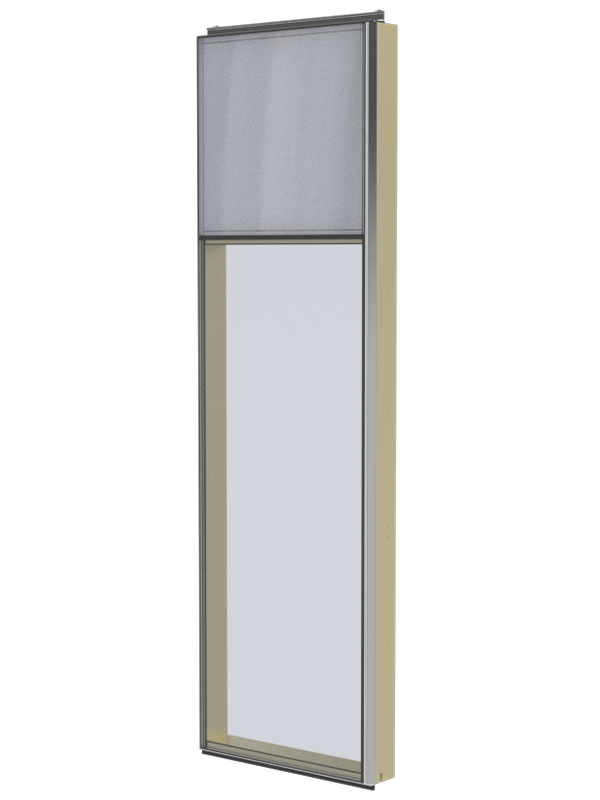

MGU-8

UNITIZED GLASS+ CURTAIN WALL SYSTEM

GLASS+

The MG Unitized Glass Curtain Wall system combines the cost control of standard glass curtain wall with the schedule advantages and precision of unitization. Our system is adaptable enough to meet modern design concepts, and responsive enough to be tailor-made to meet your projects performance and aesthetic requirements. In addition, unitizing gives us better control over the supply chain to adhere to the industry’s tight schedule demands.

Whether you are looking for an SSG butt-glazed curtain wall or a captured one with decorative mullion caps, you can feel confident knowing our MGU-8 Unitized Glass System has been tested to meet a wide range of applications. Engineered with performance built-in, our system meets the peak standards for air infiltration, water infiltration, and structural integrity. Our pre-glazed unitized curtain wall is factory assembled for elevated quality control and safety with the added benefit of year-round building erection.

Our MGU-8 Glass System was Tested and Passed the Following North American Performance Testing Standards

Performance Tests:

- ASTM E283 – Air Infiltration

- ASTM E331 – Static Water

- ASTM E501.1 – Dynamic Water

- ASTM E330 – Structural (Wind Load)

- AAMA 501.4 – Seismic

- AAMA 501.7 – Inter-Story Vertical Displacement

Simulated Tests:

- NFRC 100 – Thermal Transmittance

- NFRC 200 – Overall Solar Heat Gain

- NFRC 500 – Condensation Resistance

- AAMA 501.5 – Thermal Cycling (Largely Dependent on Glass)

*Testing data and performance is dependent on the glass used and customization changes to this baseline system*

- Best for mid-rise applications (new construction or renovation)

- Combinations of glass and rainscreen systems

- Ribbon or punched windows

- 4-sided SSG or captured

- Metal panel rainscreen cladding (see below for other options)

- Shop glazed-in metal sheathing

- Thermally broken panel supports

- Integrated mineral wool insulation

- Shop glazed infill options:

- 1-5/16″ laminated vision

- 1-5/16″ laminated spandrel

- 90° inside and outside corners *system can be customized to accommodate unique corners*

- Top of slab fully adjustable anchoring ±1″ in & out, up & down and left & right

- Engineered and tested to North American standards

- Capabilities include exterior re-glazing

- Polyamide thermal break

- Standard stack joint size requirements accommodate +/- 3/4″ of total movement for building expansion and contraction

- Screw spline shop assembly

- Inside set installation

- Fireproofing as required by code

- A variety of glass thicknesses

- Operable windows

- Rainscreen and other spandrel systems such as, but not limited to, metal panel, stone, terracotta, fiber cement, etc.

- Additional design options and sizes available for mullions, trim, brackets, and covers

- Painted finishes available in standard and custom colors, as well as anodized finishes in multiple colors

- Interior and exterior can be two different colors/finishes

- Available spandrel back panning with enhanced pressure equalized venting/weeping options

- Sunshade add-on options available

- Steel reinforcing available for chassis

- Stiffener reinforcing for large panels

- Can be outside set installation if required

- Design options and sizes available for trim

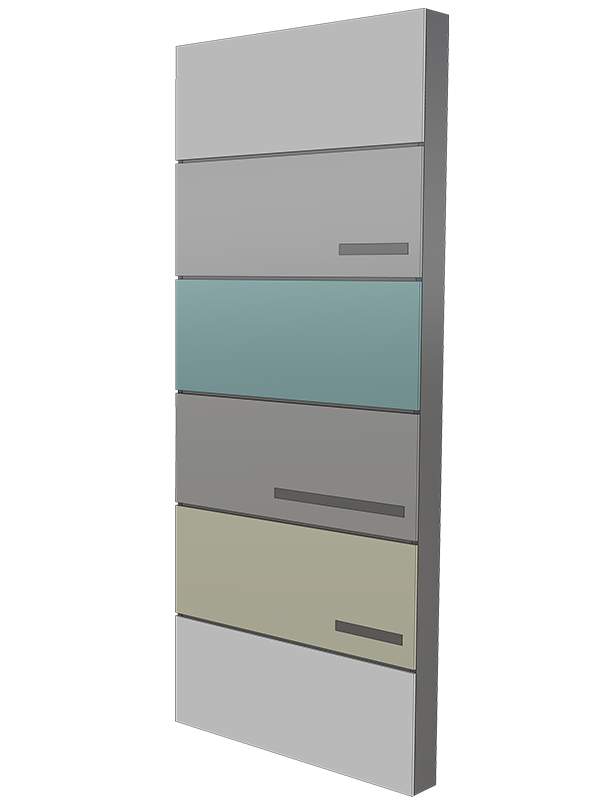

UNITIZED METALS+ SYSTEMS

METALS+

In addition to unitized glass curtain wall, MG McGrath has extensive experience delivering many other types of unitized façade materials such as metal, composite, and terra cotta.

Traditional full enclosure assemblies, rainscreen cladding, and larger sections of scrim, can all be customized in a unitized system that meets the schedule and performance of your project.

- Best for mid-rise applications (new construction or renovation)

- Metal panel rainscreen cladding (see below for other options)

- Shop glazed-in metal sheathing

- 90° inside and outside corners *system can be customized to accommodate unique corners*

- Top of slab fully adjustable anchoring ±1″ in & out, up & down and left & right

- Engineered and tested to North American standards

- Thermally broken panel supports

- Integrated mineral wool insulation

- Standard stack joint size requirements accommodate +/- 3/4″ of total movement for building expansion and contraction

- Screw spline shop assembly

- Inside set installation

- Fireproofing as required by code

- Rainscreen Cladding Options: (add in rainscreen options list)

- Design options and sizes available for trim

- Painted finishes available in standard and custom colors, as well as anodized finishes in multiple colors

- Steel reinforcing available for chassis

- Stiffener reinforcing for large panels

- Can be outside set installation if required

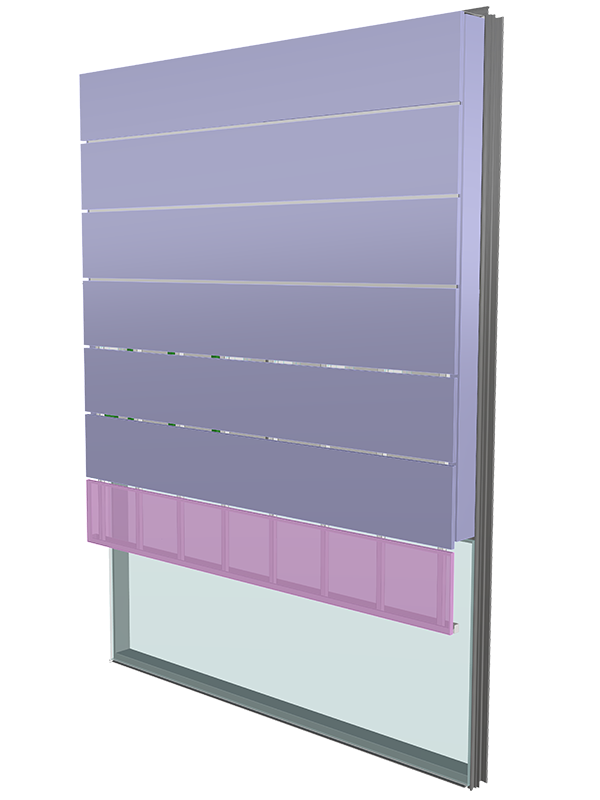

UNITIZED COMBO SYSTEMS

GLASS+ AND METALS+ IN ONE SYSTEM

We also have the capabilities to combine our Glass+ and Metals+ systems into one unitized combo system making fabrication and installation even faster and more versatile.

Glass and metal sheathing are glazed into our unitized curtain wall chassis with insulation, girts, and rainscreen panels applied to create a combo system that is high-performing and flexible to accommodate a wide range of aesthetics.

The advantage of using an MG McGrath unitized system is having an industry-leading, single-source option for your façade needs. We provide unmatched opportunities to have metals+ and glass+ combined in one unitized system fully fabricated and installed by our team.

- Best for mid-rise applications (new construction or renovation)

- Combinations of glass and rainscreen systems

- Ribbon or punched windows

- 4-sided SSG or captured

- Metal panel rainscreen cladding (see below for other options)

- Shop glazed-in metal sheathing

- Thermally broken panel supports

- Integrated mineral wool insulation

- Shop glazed infill options:

- 1-5/16″ laminated vision

- 1-5/16″ laminated spandrel

- 90° inside and outside corners *system can be customized to accommodate unique corners*

- Top of slab fully adjustable anchoring ±1″ in & out, up & down and left & right

- Engineered and tested to North American standards

- Capabilities include exterior re-glazing

- Polyamide thermal break

- Standard stack joint size requirements accommodate +/- 3/4″ of total movement for building expansion and contraction

- Screw spline shop assembly

- Inside set installation

- Fireproofing as required by code

- A variety of glass thicknesses

- Operable windows

- Rainscreen and other spandrel systems such as, but not limited to, metal panel, stone, terracotta, fiber cement, etc.

- Additional design options and sizes available for mullions, trim, brackets, and covers

- Painted finishes available in standard and custom colors, as well as anodized finishes in multiple colors

- Interior and exterior can be two different colors/finishes

- Available spandrel back panning with enhanced pressure equalized venting/weeping options

- Sunshade add-on options available

- Steel reinforcing available for chassis

- Stiffener reinforcing for large panels

- Can be outside set installation if required

- Design options and sizes available for trim