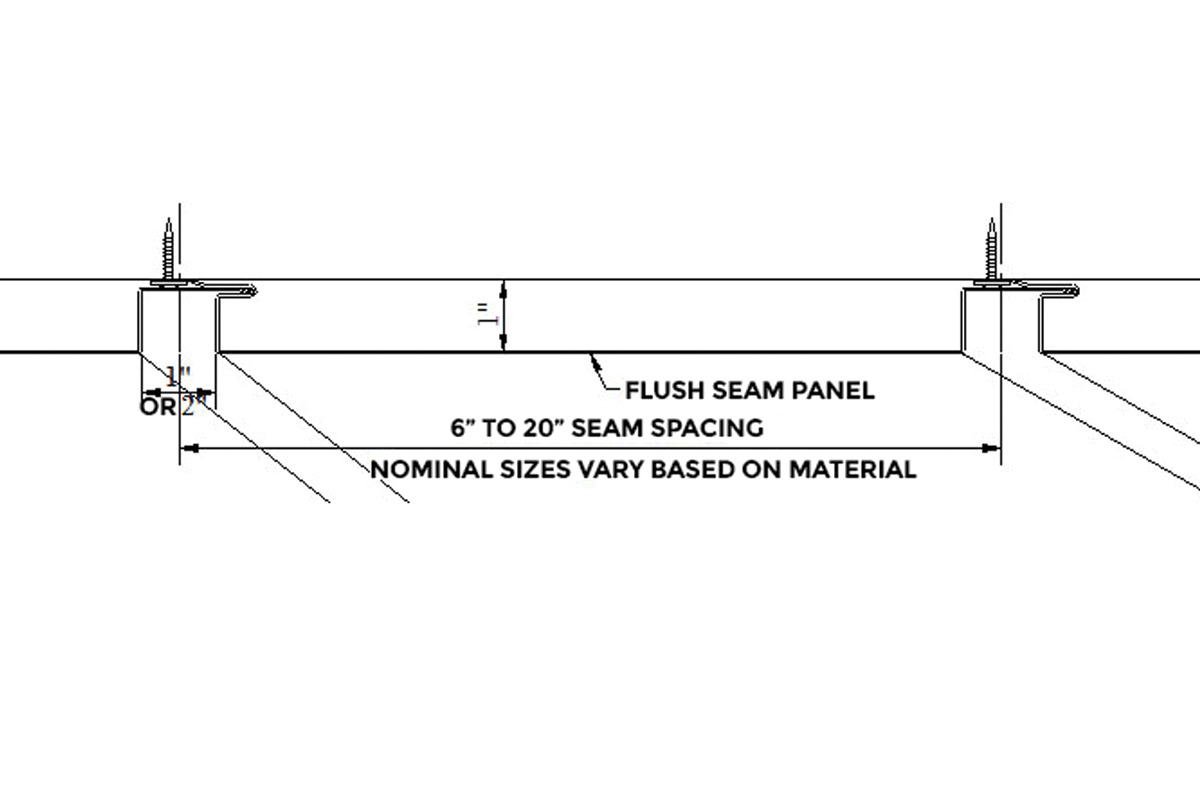

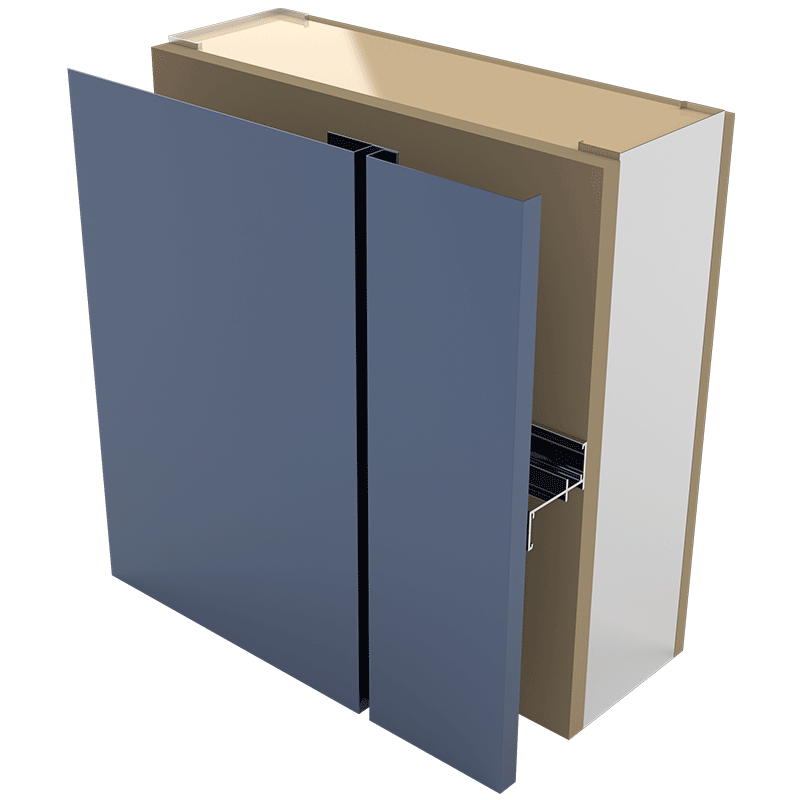

The MG R-Seam panel system is a uniform system that offers a smooth, flat appearance for either horizontal or vertical applications. Panels are joined together using an interlocking slip connection and are mechanically fastened with concealed fasteners to form a flush reveal joint. These recessed reveal joints really set this system apart because they are formed continuously for the sought-after continuity look. The system is installed with panels overlapped and sealed in a sequential pattern, as required to form a watertight system. The architectural rib option stiffens the panels even further to reduce oil canning

MG R-SEAM

FLUSH SEAM STYLE PANEL SYSTEM

PANEL COMPOSITION

MATERIAL OPTIONS & FINISHES

| MATERIAL | THICKNESS | FINISHES |

| Steel | 22 – 26 gauge | MG steel custom patina finishes, or standard and custom colors |

| Stainless | 24 – 26 gauge | Standard and custom colors available |

| Aluminum | .032” & .125” | Standard and custom colors available |

| Copper | 16oz, 20oz, & 24oz | MG copper custom patina finishes |

| Zinc | .7mm to 1.5mm | MG zinc custom patina finishes, or standard and custom colors |

| Titanium | 26 gauge | Standard and custom colors available |

*Material, sizes, and spacings are rough estimates. Capabilities and options vary as material gauge and panel length fluctuate. Please contact us for a more detailed range of capabilities as engineering allows*

TECHNICAL DATA & SPECIFICATIONS

FEATURES & OPTIONS

Features & Options

-

Includes interlocking slip connection clips and stiffeners if required

-

Panel system to accommodate substructure tolerance of +0 to -1/8 inch

-

Panels can be installed vertically or horizontally over almost any substrate

-

Custom alloys available based on material choice

-

Variable reveal width