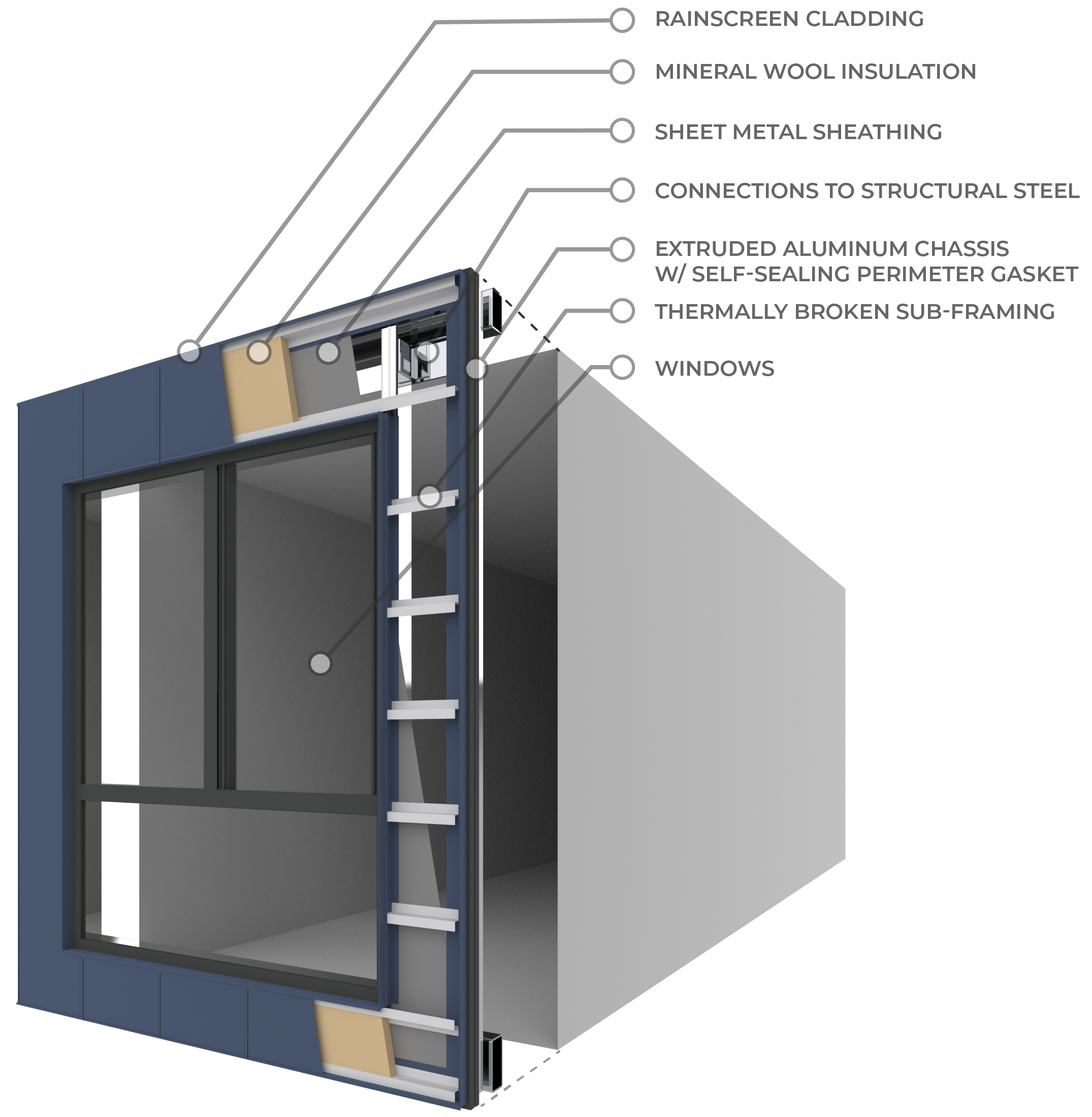

MG McGrath has applied many of the same principles behind unitization to modular construction. While the two types are similar, the main differences are the installation methods and connection style. Compared to traditional field-built structures, modular construction can often be faster, safer, and just all-around better quality.

At MG McGrath, we have a dedicated assembly facility specifically geared towards the production of our modular facades with skilled craft workers at each station. We combine the ingenuity of mass production with the quality, skill, and passion of our custom fabrication. Whether you want us to supply-only or to supply and install, we are set up to accommodate your modular project needs.