WILLISTON BASIN INTERNATIONAL AIRPORT

WILLISTON, ND

This new $275 million airport doubled the size of the existing one and still leaves room for future expansion

PROJECT INFORMATION

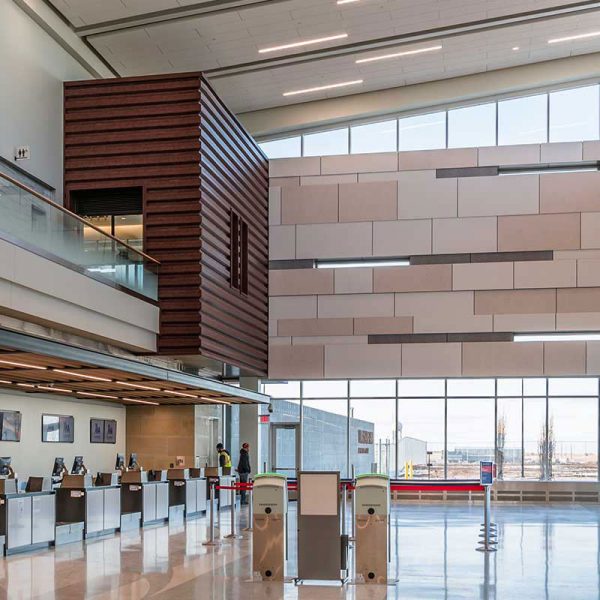

A booming North Dakota economy gave way to the construction of the new Williston Basin International Airport (XWA). This new airport replaces the previous Sloulin Field International Airport which was deemed too small for the increase in traffic even after an addition in 2005. The Williston Basin International Airport more than doubles the size of the old airport making room for amenities like faster TSA screening devices, rental car services, and larger jet accommodations. The new airport now has a 110,000 square foot terminal, four gates, three passenger boarding bridges, two runways a full-service restaurant, a baggage claim, children’s play area, and more lounge seating

PROJECT SCOPE

On the exterior of the project, MG McGrath provided several metal panel rainscreen systems in a variety of applications. The West, North, and South elevations and interior walls are clad with over 19,000 square feet of Centria MR3-36 corrugated panels in an Allusion Rust finish. These panels also feature factory and shop mitered corners, wrapping the window openings and corners of the building. Approximately 12,500 square feet of Centria Formawall panels in flat and embossed finishes, Silversmith and Dark Bronze colors, were installed at the stair enclosures, tapering soffits, and the East elevation overhang. The overhang features a complicated design with a 5-step soffit and fascia configuration. Some of the insulated panels had to be manufactured in parallelogram shapes to be installed at sloped fascias, while maintaining true vertical joints. Approximately 2,500 square feet of a CS-200 panel system in Dark Bronze finish was also installed at the bridge abutments and interior soffits. The main entrance elevation and North/South returns featured a beautiful 10,000 square foot Dri-Design enclosure in custom Champagne Anodized finish developed specifically for this project with Clear Anodized accents. All of the Centria MR3-36 and Dri-Design panels were installed over a thermally broken Greengirt with 5″ insulation depth. McGrath provided the thermal girts and mineral wool insulation as part of the enclosure. The interior of the project also included Dri-Design panels at the interior window openings and elevator enclosures. In addition to all of the paneling, MG McGrath also installed custom stainless-steel trims and fin tube covers. The bulk of the project was completed over the winter months, with record-breaking temperatures dipping well below 0