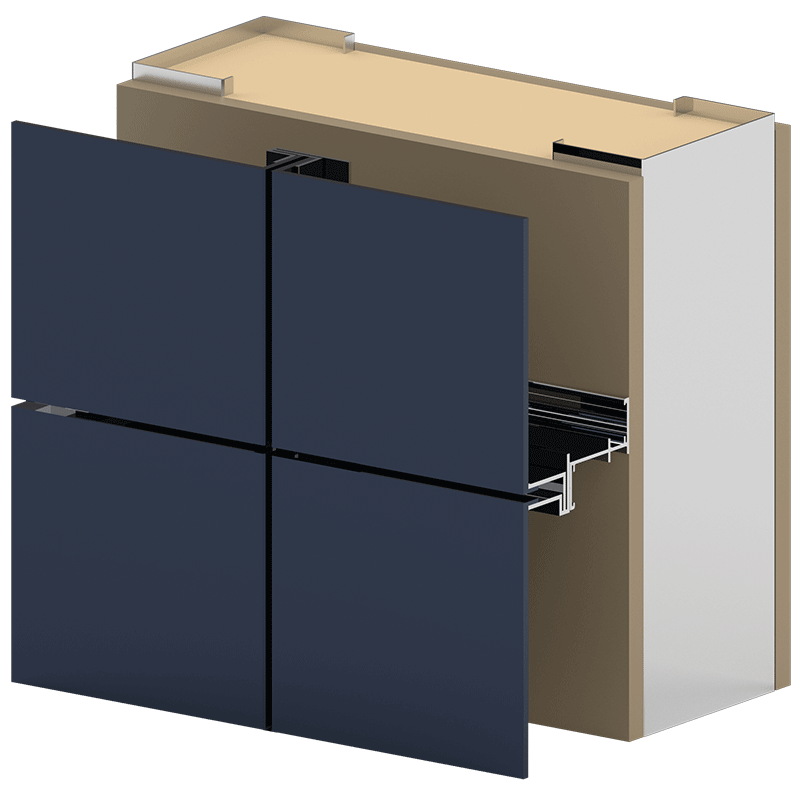

The MG-Plate panel system offers meticulous accuracy and consistent design. Panels are fabricated with automated CNC Router technology to insure precise joinery and tolerance. Materials can be radius, straight, or tapered to achieve any desired appearance along with rout and return flange options available in various sizes. MG-Plate panels can be installed over a wide variety of various substrates to meet the needs of your project

MG PLATE

PLATE & COMPOSITE STYLE PANEL SYSTEM

PANEL COMPOSITION

MATERIAL CHOICES & FINISHES

| MATERIAL | THICKNESS | FINISHES |

| Steel | .080” – .125” | MG steel custom patina finishes, or standard and custom colors |

| Stainless | .080” – .125” | Standard and custom colors available |

| Aluminum | .080” – .125” | Standard and custom colors available |

| Copper | .080” – .125” | MG copper custom patina finishes |

| Zinc | .080” – .125” | MG zinc custom patina finishes, or standard and custom colors |

*Materials, sizes, and thicknesses are general guidelines and estimates. Capabilities and options may vary as material gauge and panel length fluctuate. Please contact us for a more detailed range of size options and capabilities based on your project’s requirements and design intent (as engineering allows)*

TECHNICAL DATA & SPECIFICATIONS

FEATURES & OPTIONS

Features & Options

-

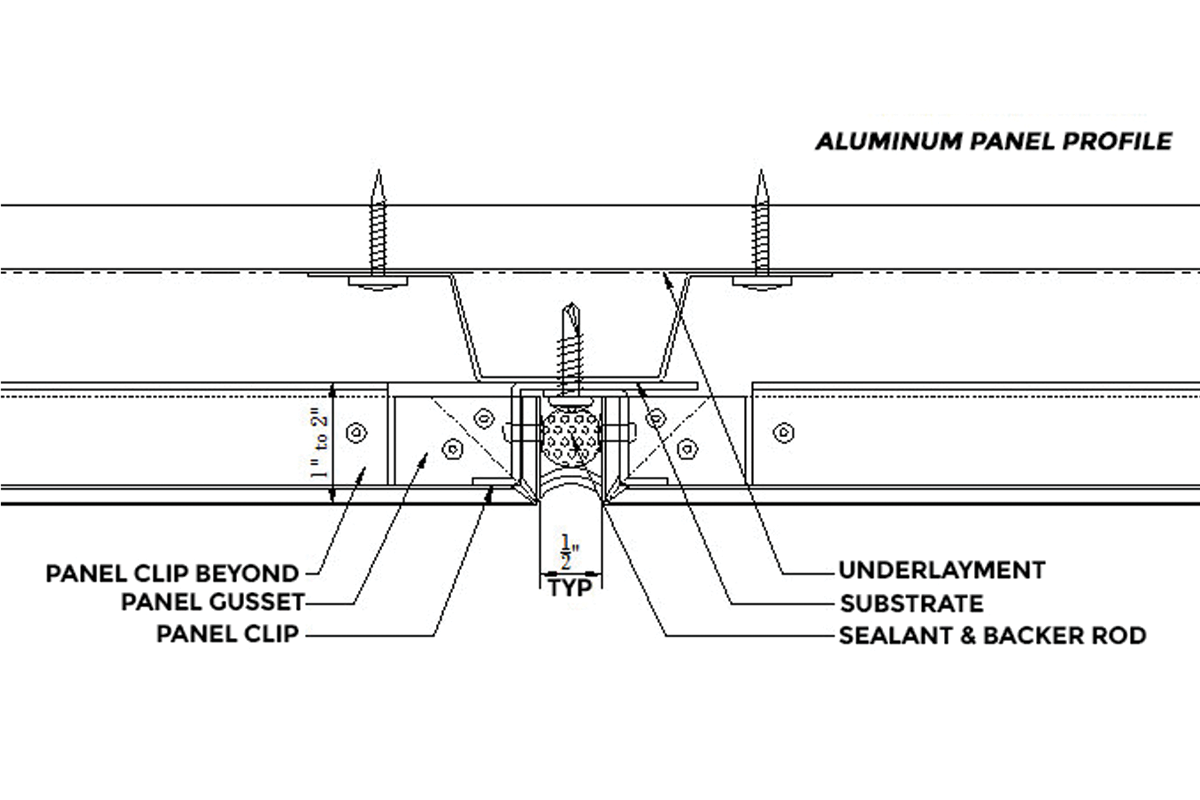

Includes panel clips and stiffeners if required

-

Panel system to accommodate substructure tolerance of +0 to -1/8 inch

-

Panels can be installed over almost any substrate

-

Custom alloys available based on material choice